Automatic Stator Coil Winding Machine

- group name

- Stator winding machine

- Min Order

- 1 piece

- brand name

- NIDE

- model

- RXL2-160

- Nearest port for product export

- SHANGHAI, NINGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right

- update time

- Tue, 18 Oct 2016 14:24:06 GMT

Paramtents

Function wind coils for stator

application motor stator

condition new

working station two

certificate CCC

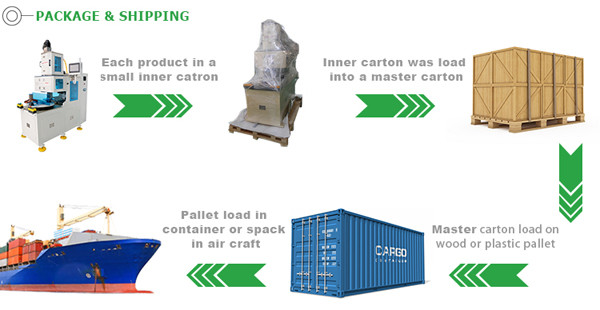

Packging & Delivery

- 180cm x 110cm x 220cm

-

Min Order1 piece

Briefing

Detailed

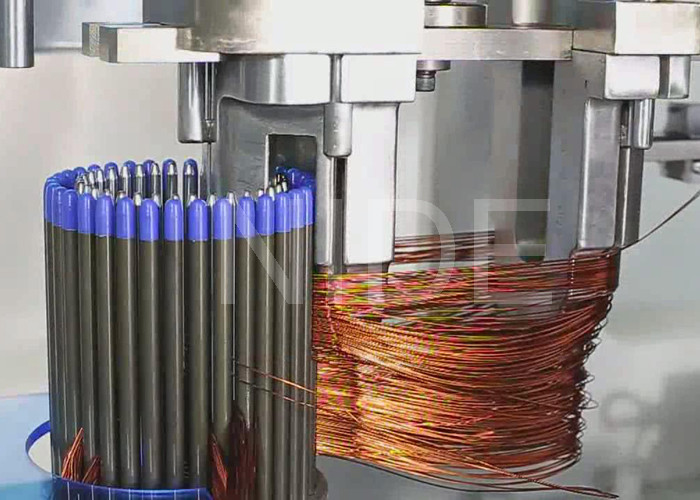

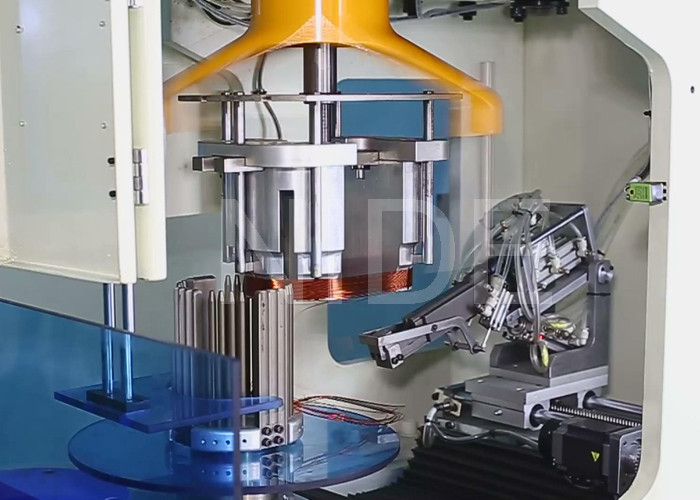

This stator coil automatic winding machine is especially suitable for coils winding in the stator of high slot filling rate but small slot notch; single-head and double-station automatic winding machine; It automatic put the coil into transfer former orderly. Winding mode such as automatic skip, automatic cutting and automatic indexing can be finished at a time successively; Parameter could be set in human-machine interface, winding tension is adjustable; Obtain continuous/discontinuous winding way and meets the 2 poles, 4 poles and 6 poles coils winding,

Main technical data

Winding head: 1pc

Wire diameter: 0.17~1.2mm

Winding speed: ≤2200RPM

Max flier track: ¢400mm

Transfer number: 2~6section

Power supply:380V/50/60HZ 7KW

Weight: about 1100kg

Dimension: L1800*W1100*2200mm

Machine main function and characteristic

1. Winding tooling: each machine has one set winding tooling and three vertical winding forms.

2. The whole set of tooling can be changed, and it takes about 15min.

3. The turntable is two stations structure. It adopts servo system to rotate and index transfer form.

4. Allow three wires winding simultaneously.

5. Main spindle is controlled by servo motor. The coil turn number accuracy is ±1 turn.

6. The working rotation speed can be set . Machine has no distinct vibration and noise.

7. Free of enamel damage and wire snap. Once the copper wire is run out, machine will automatically stop.

8. PLC can set turn number, winding speed, tooling sunk height, tooling sunk speed and winding direction.

9. X and Y spindle of wire hooker and wire cutter adopts servo system. It can adjust the length of bridge wire and lead wire.

10. Tooling sunk adopts servo system. The max segment number of tooling sunk is 6.

Main components

Servo motor:Mitsubishi

Control system: Yitu Taiwan

Touch screen:Tongtai

Sensor: Autonics

Switch and Button: Schneider

Other electric parts: Delixi /Schneider