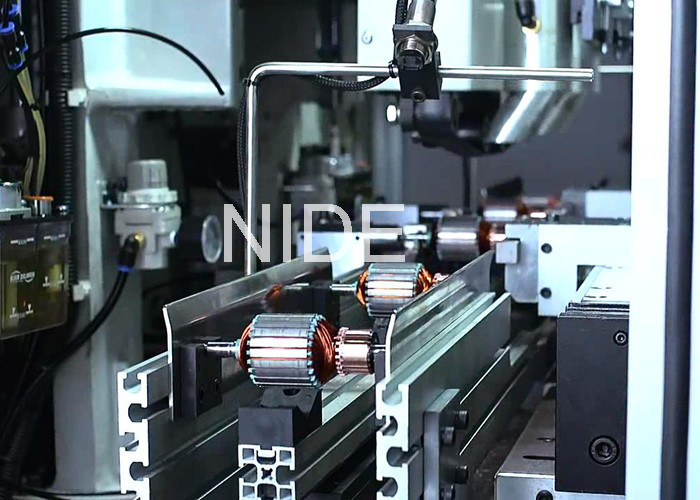

S2type Automatic Mixer armature production machine assembly line

- group name

- Armature production line

- Min Order

- 1 piece

- brand name

- NIDE

- model

- ND-ZZX-1

- Nearest port for product export

- SHANGHAI, NINGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right

- update time

- Tue, 06 Sep 2016 13:39:23 GMT

Paramtents

Machine color RAL9010 or as Per Customer Requireme

Certificate CCC

Automation type fully automatic

After-Sales Service Overseas Service Center Available

Customized service Available

Contorl method controlled by PLC

tooling change process easy

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

This armature production line is of high automation. It greatly improve the working efficiency, only two or three people needed for opreating. It is labor cost saving.

This production line can be produced in two different process according to client's requirements.The whole production is of high automation.

Process 1:

Shaft press---end field press---commutator press----armature insulation paper inserting---armature winding—commutator welding----wedge inserting---armature testing.

The electric motor production line including: shaft pressing machine, end plate pressing machine, commutator pressing machine, armature insulation paper inserting machine, armature winding machine, commutatorhot stacking machine, armature wedge inserting machine and armature testing machine.

Process 2:

Armature insulation paper inserting---armature winding—commutator welding----wedge inserting—- armature testing.

There are three kinds of production line according to different conveyor: S1, S2 and S3.

S1: Support the armature on the armature shaft, this way maybe damage the shaft.

S2: Support the armature on the lamination, it can protect the shaft and has low noise.

S3: Put the armature on a conveyor plate, it can protect the shaft, lower noise and has nice appearance.

Information needed for armature production line inquiry

It will be better if customer could send us detailed drawing including below information.

1. Rotor lamination drawing

2. Rotor assemble drawing

3. Rotor stack drawing

4. Rotor winding diagram drawing: with rotor wire diameter and turn number

5. Commutator drawing

6. Shaft drawing

7.End cover drawing

8. Required residual unbalancing volume and initial unbalancing volume

9 Wedge and insulation paper material

10. Required productivity

11. Other technical requirement

If possible, it will be better if customer can send us samples.

The working station of this armature production line