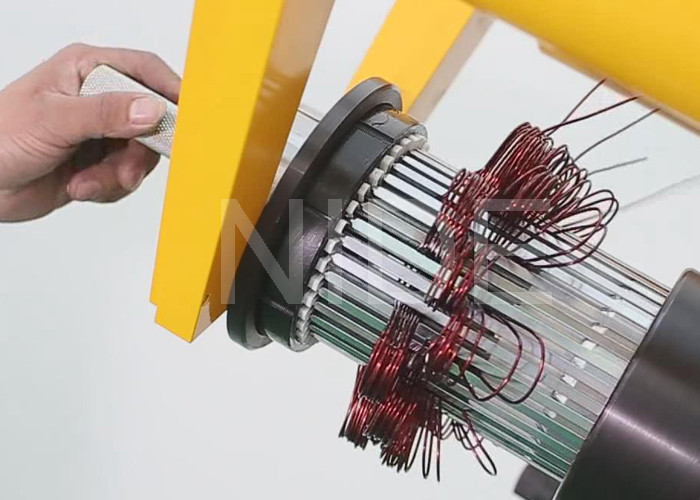

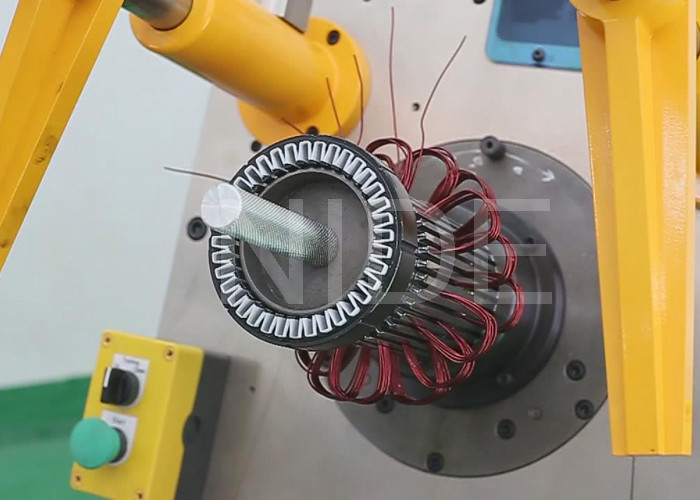

Servo Coil and Wedge Inserting machine

- group name

- Stator winding inserting machine

- Min Order

- 1 piece

- brand name

- NIDE

- model

- QX1-150/160

- Nearest port for product export

- SHANGHAI, NINGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right

- update time

- Tue, 06 Sep 2016 14:36:28 GMT

Paramtents

Certification CCC

After-Sales Service Overseas Service Center Available

Machine size Middle size

Condition New

Customized service Available

Packging & Delivery

- 180cm x 65cm x 170cm

-

Min Order1 piece

Briefing

Detailed

Suitable for inserting coil and wedge into stator slot by servo system;can insert the coil and wedge in the mid of slot into stator at a time;wedge feeding is to be done by stepping motor,coil and wedge inserting is by servo system;different parameter could be set in human-machine interface;the speed and feeding mode is acquirable according to different slot filling rate and different kind of wire;different size stator prodcution can be achieved by changing tooling;especially apply to micro induction motors such as air conditioner motor,washing machine motor,compression motor,fan motor,generator motor and pump motor.

Specification

Stator stack length:10--150mm

Stator OD:Max. 160mm

Stator ID:30~110mm

Tooling traveling distance:Max.60mm

Slot number:8~48slots

Max. slot filling rate:80%

Power:380V/50/60HZ 3Kw

Machine weight:about 850kg

Machine dimension:L1850*W650*1700mm

Main components

PLC:Mitsubishi

Servo motor:Mitsubishi

Wedge feeding motor:Sihai

Touchscreen:Tongtai

Cylinder:SMC

Sensor:Autonics

Switch and Button:Schneider

Other electric parts:Delixi /Schneider

Machine main function and characteristic

l The machine insert coil and wedge simultaneously, coil insertion is controlled by servo motor system , and wedge insertion by variable frequency motor.

l It is controlled by HMI, and machine can diagnose breakdown automatically.

l This machine is suitable for Polyester Film wedge roll material with fixed thickness and fixed width (width and thickness dimension is provided by customer)

l The wedge feeding is by stepping motor, feeding length, cutting, forming, inserting slot number could be set.

l Both copper wire and aluminium wire are appliable.

l Production capacity ≤25s/set (exclude the man-hours for auxiliary work)

l Primary qualification rate for copper wire ≥98.5%, after rework, the rate ≥99.5%

l Both wedging system and feeding system have pre-decelerating function.

l This machine has alarm for material runout.

l Wire pushing height and stop time can be set in the HIM interface.

l This machine has fixed foot and removable wheel.

l Wedge should not be damaged, no burr in the surface, no movement or slide.

l Slot paper should not be damaged, no movement or slide. Copper wire should not be pull away from the paper.

l The stator should not be deformation or stator lamination should not be upward.